What is Diecast Aluminum

Diecast aluminum is a highly efficient manufacturing process that involves forcing molten aluminum under high pressure into a mold cavity. This process produces intricate, net-shape parts with excellent dimensional accuracy and surface finish. The diecasting process is widely used across various industries, owing to its ability to create complex geometries and high production volumes. Diecast aluminum components are known for their strength, lightweight properties, and corrosion resistance, making them ideal for a wide range of applications. This guide is designed for beginners, providing a comprehensive overview of the diecast aluminum process, alloys, applications, advantages, disadvantages, and essential tips.

The Diecast Aluminum Process

The diecast aluminum process is a sophisticated manufacturing technique that offers numerous benefits in terms of efficiency, precision, and material properties. Understanding this process is crucial for anyone looking to leverage its advantages. The process typically involves several key stages, each contributing to the final product’s quality and characteristics. From mold preparation to ejection and trimming, each step is vital for achieving the desired outcome. Let’s explore the step-by-step procedure involved in diecast aluminum casting, to provide a comprehensive overview of this manufacturing technique.

Step-by-Step Diecast Aluminum Casting

Preparing the Mold

The first step involves preparing the mold, which is a critical aspect of the diecasting process. Molds, also known as dies, are typically made from high-strength tool steel to withstand the high pressures and temperatures involved in the process. Before each casting cycle, the mold is cleaned and lubricated to facilitate the smooth flow of molten aluminum and to prevent the casting from sticking to the die. The mold is meticulously inspected for any defects or wear that could compromise the quality of the final product. Proper mold preparation ensures dimensional accuracy and a high-quality surface finish.

Melting and Injecting the Aluminum

Once the mold is prepared, the aluminum alloy is melted in a furnace to a specific temperature. The molten aluminum is then injected into the mold cavity under high pressure. The injection pressure is carefully controlled to ensure that the molten metal fills the mold completely and uniformly. This process is typically performed using a diecasting machine, which precisely controls the injection parameters. The high-pressure injection is what gives diecast parts their intricate detail and fine surface finish. The molten aluminum solidifies quickly inside the mold, taking the shape of the cavity.

Cooling and Solidification

After the molten aluminum is injected, it needs to cool and solidify within the mold. The cooling process is crucial for the mechanical properties and dimensional stability of the diecast part. Cooling rates are carefully managed, often with cooling channels built into the die to remove heat efficiently. The solidification process transforms the molten metal into a solid state, taking the shape of the mold cavity. The duration of the cooling cycle depends on the size and complexity of the part, as well as the alloy used. Effective cooling prevents defects such as porosity and ensures that the final product meets quality standards.

Ejecting and Trimming the Casting

Once the part has solidified, it is ejected from the mold. Ejection pins are used to push the casting out of the die. After ejection, the casting may still have some excess material, such as flash or gates, which needs to be removed. Trimming operations are performed to remove these unwanted materials, often using trimming dies or other specialized equipment. The trimmed casting undergoes further finishing processes if needed, such as machining, surface treatment, or painting. The final casting is then ready for use in its intended application.

Diecast Aluminum Alloys

The choice of alloy significantly influences the mechanical properties, corrosion resistance, and overall performance of a diecast aluminum component. Different alloys are specifically formulated to meet the requirements of various applications. Selecting the right alloy is critical for the success of a project. Aluminum alloys used in diecasting are typically composed of aluminum combined with other elements, such as silicon, copper, magnesium, and zinc. These elements are added to enhance specific properties such as strength, hardness, and corrosion resistance.

Common Diecast Aluminum Alloys

Several aluminum alloys are commonly used in diecasting. These alloys offer a range of properties suitable for various applications. The selection of an alloy depends on the specific requirements of the part. The most common alloy is A380, known for its excellent combination of strength, castability, and cost-effectiveness, making it suitable for a wide range of applications. Other common alloys include A383, A360, and A413, each offering unique characteristics in terms of strength, ductility, and corrosion resistance. Each alloy’s composition and properties determine its suitability for different applications. Different alloys also affect the casting process and final product characteristics.

Properties of Diecast Aluminum Alloys

Diecast aluminum alloys offer several desirable properties that make them suitable for various applications. They are known for their high strength-to-weight ratio, excellent corrosion resistance, and good thermal and electrical conductivity. The specific properties vary depending on the alloy composition and manufacturing process. The mechanical properties, such as tensile strength, yield strength, and elongation, are crucial for structural applications. Corrosion resistance ensures the longevity of the components, especially in harsh environments. Thermal and electrical conductivity are important for applications requiring heat dissipation or electrical performance. The careful consideration of these properties is essential when selecting a suitable alloy.

Advantages of Diecast Aluminum

Diecast aluminum offers several significant advantages over other manufacturing processes, including high production rates, the ability to produce complex shapes, and an excellent surface finish. These benefits make it a preferred choice for many industries. Furthermore, the inherent properties of aluminum, such as lightweight and corrosion resistance, add to the appeal of diecast aluminum components. The advantages contribute to cost savings, improved product performance, and reduced environmental impact.

High Production Rates

Diecasting is capable of producing large volumes of parts in a short amount of time. This high-speed manufacturing makes it an ideal choice for mass production. The rapid cycle times and efficient process contribute to cost-effectiveness. The process allows for the manufacturing of thousands of parts per day, which is essential for meeting high-volume demands in industries like automotive and consumer electronics. Diecasting machines automate many of the production steps, reducing the need for manual labor and improving efficiency.

Complex Shapes

Diecasting excels at producing intricate and complex geometries that are difficult or impossible to achieve with other manufacturing methods. The process allows for the creation of parts with thin walls, fine details, and complex features. This capability opens up design possibilities that were previously limited. The ability to create complex shapes allows for the integration of multiple functions into a single part, reducing the need for assembly and improving overall product performance. The flexibility allows designers to create innovative and efficient product designs.

Good Surface Finish

Diecast aluminum parts typically have a smooth surface finish, requiring minimal post-processing. This high-quality surface reduces the need for extensive finishing operations, such as machining or polishing, which saves time and money. The smooth surface also provides an excellent base for coatings and paints. The ability to achieve a high-quality surface finish directly from the casting process enhances the aesthetic appeal and functional performance of the parts. This makes diecast aluminum parts an attractive option in industries where visual appearance is important, such as consumer electronics and automotive.

Disadvantages of Diecast Aluminum

While diecast aluminum offers numerous advantages, it also has some disadvantages. The primary drawbacks include the high initial investment required for tooling and the potential for porosity in the finished parts. Understanding these limitations is important to make informed decisions about whether diecasting is the right choice for a specific project. Considering these factors helps in mitigating potential challenges and ensuring the successful implementation of the diecasting process.

High Initial Investment

The initial investment in diecasting can be substantial, primarily due to the cost of designing and manufacturing the dies. Dies are complex and precisely engineered tools, and their cost can be a barrier for small production runs or projects with limited budgets. The high upfront cost needs to be offset by the benefits of mass production and lower per-unit costs. The investment is often justified for high-volume production runs, where the cost is amortized over a large number of parts. Careful planning and cost analysis are crucial to assess the feasibility of diecasting for a specific project.

Porosity

Porosity, or the presence of small voids or air pockets within the casting, is a common issue in diecast aluminum. Porosity can reduce the strength and mechanical properties of the part. It can also affect its ability to be heat-treated or welded. While efforts are made to minimize porosity, such as using vacuum systems, it is a potential concern that needs to be addressed. The extent of porosity depends on factors like alloy composition, die design, and casting parameters. Quality control measures, such as X-ray inspection, are often used to identify and manage porosity.

Applications of Diecast Aluminum

Diecast aluminum is used across a wide range of industries, thanks to its versatility and excellent performance characteristics. Its applications span various sectors, including automotive, consumer electronics, and aerospace. The unique properties of diecast aluminum, such as lightweight, high strength, and corrosion resistance, make it ideal for these diverse applications. This versatility allows for innovative solutions and the creation of efficient and durable components.

Automotive Industry

The automotive industry is a major user of diecast aluminum, with components used in engines, transmissions, and structural parts. The lightweight and strong properties of aluminum help reduce vehicle weight, improving fuel efficiency and performance. Common applications include engine blocks, cylinder heads, transmission housings, and various brackets and supports. Diecast aluminum components are also used in safety systems, such as airbags and anti-lock braking systems. The ability to create complex shapes and integrate multiple functions makes diecasting a preferred choice for many automotive components.

Consumer Electronics

Diecast aluminum is also widely used in consumer electronics, where it provides both structural support and aesthetic appeal. The excellent surface finish and lightweight properties make it suitable for housings, enclosures, and heat sinks. Common applications include laptop computer cases, smartphone frames, and camera components. Diecast aluminum components also help dissipate heat, preventing overheating of sensitive electronics. The versatility in design and the ability to produce complex shapes make diecasting a desirable option for consumer electronics manufacturers.

Aerospace Industry

The aerospace industry utilizes diecast aluminum for components requiring high strength, lightweight, and reliability. These components are used in aircraft engines, structural parts, and interior components. The aerospace industry demands materials that can withstand extreme conditions and meet stringent safety standards. The high strength-to-weight ratio and corrosion resistance of diecast aluminum make it suitable for these demanding applications. Specific components include engine housings, control surfaces, and various brackets and supports. The ability to produce complex and precise components is critical in the aerospace industry, making diecasting a preferred manufacturing method.

Tips for Beginners

If you are new to diecast aluminum, here are some tips to help you navigate the process. Understanding the key factors and best practices will contribute to successful outcomes. These tips encompass alloy selection, design considerations, and post-processing techniques. Focusing on these elements will optimize the diecasting process and ensure the production of high-quality parts. Always consult with experienced professionals for specific project guidance.

Choosing the Right Alloy

Selecting the appropriate aluminum alloy is crucial for the performance of the diecast part. The choice of alloy should be based on the required mechanical properties, corrosion resistance, and application environment. Carefully consider the specific requirements of your project. Factors to consider include tensile strength, yield strength, elongation, and the operating temperature. Consult with alloy suppliers and diecasting experts to determine the best option. By carefully selecting the alloy, you can ensure that the final product meets the required specifications and performs reliably.

Designing for Diecasting

When designing a part for diecasting, consider the specific requirements of the process. Designing with diecasting in mind can significantly improve the manufacturability and cost-effectiveness of the part. Ensure that the design includes features that facilitate mold filling, ejection, and trimming. Consider the draft angles, wall thickness, and other design elements to optimize the process. Consult with diecasting experts early in the design phase to get advice on design modifications that can improve the part’s performance and reduce manufacturing costs. By designing with the diecasting process in mind, you can create parts that are both efficient to manufacture and high-performing.

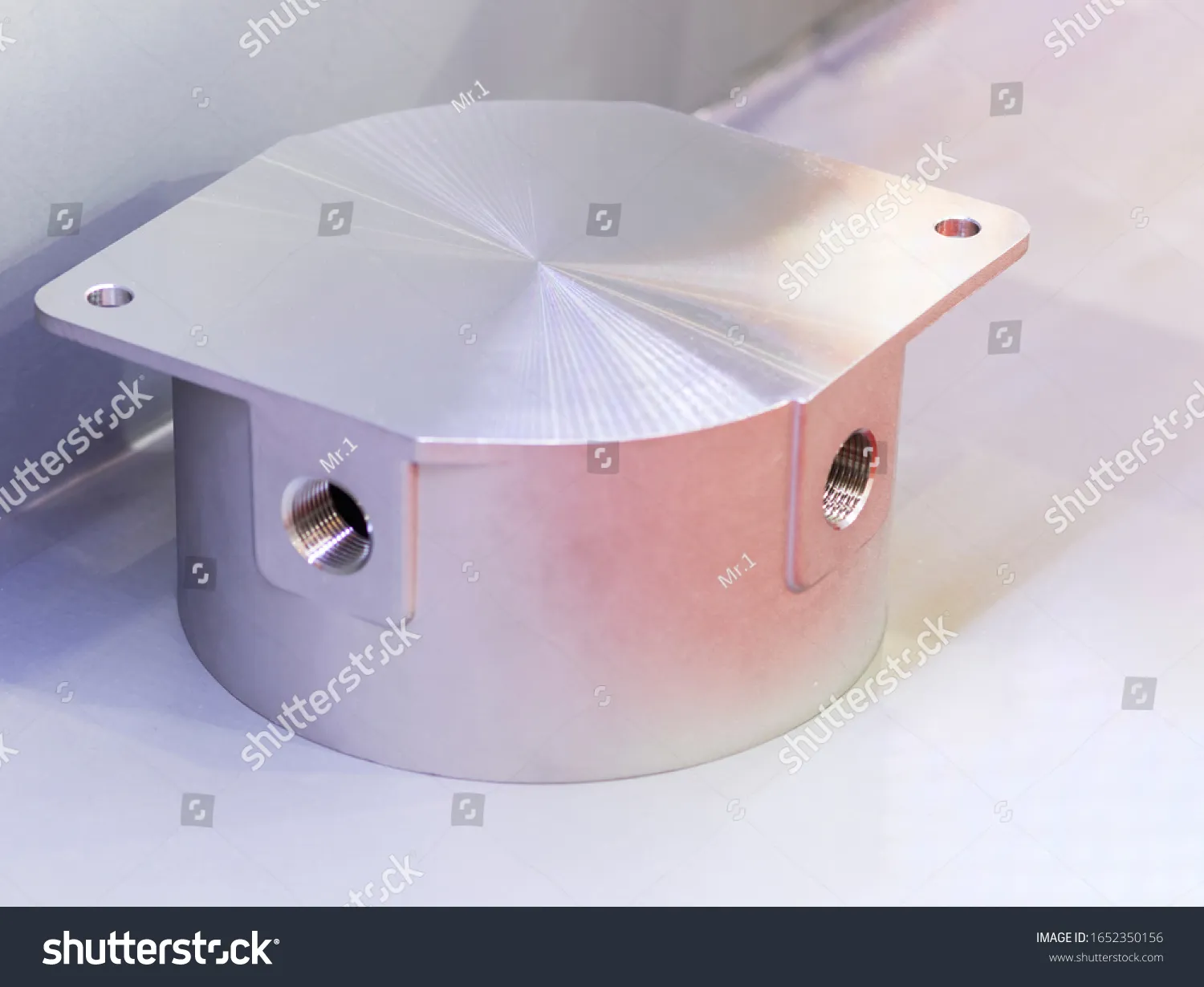

Post-Processing Techniques

After the casting process, the parts may require post-processing steps to achieve the desired finish and functionality. Common post-processing techniques include machining, surface treatments, and coatings. Machining may be needed to achieve precise dimensions or to create additional features. Surface treatments, such as anodizing or powder coating, can improve corrosion resistance and enhance the appearance of the part. The selection of post-processing techniques depends on the specific requirements of the application. Post-processing can refine the part, achieving the final desired properties. Careful consideration of these techniques ensures that the diecast aluminum parts meet the required specifications.

Conclusion

Diecast aluminum is a versatile and efficient manufacturing process that offers numerous advantages for various applications. Understanding the process, the alloys, and the design considerations will empower you to leverage its benefits. From automotive components to consumer electronics, diecast aluminum plays a significant role in modern manufacturing. As a beginner, this guide provides a solid foundation for understanding the intricacies of diecast aluminum. By following the tips and considering the advantages and disadvantages, you can successfully implement diecasting in your projects, creating high-quality, reliable, and cost-effective components for a wide range of industries. Continuous learning and collaboration with industry experts will further enhance your understanding and capabilities in the world of diecast aluminum.